The 3D-printer has been working overtime for the last few days making me a new little drawer unit that looks like this:

View attachment 29571

It's screwed into the shelf above. The bottom drawer has lots of screwdriver bits:

View attachment 29573

The middle one has hex-shank drills:

View attachment 29574

The top one has miscellaneous related clutter:

View attachment 29575

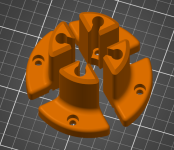

What's slightly unusual about it (and which took a bit of thinking about) is that the drawers are captive but able to tilt, so when they're fully open, they look like this:

View attachment 29572

That means I can use that long 3D-printed strip at the top for storing screwdrivers in a more compact way than before but still see what's in the drawers when they're open:

View attachment 29576

The design wasn't perfect: I needed to tweak the height of the drawers slightly, but it was close enough that I just did that with a block plane rather than bothering reprinting!